Computer Controlled Machining

In this assignment i learned how to use the shopbot machine to build different things. The first part of my experience was exploring different alternatives of pressfit unions.

To work with the Shopbot is important to know:

The tolerance: One important thing to consider in a pressfit union is the tolerance, it depend of the material and the mechanical properties.

The correct mill: For the materials in fablab, MDF, Plywood. I was using the 6mm mill, for details the 3mm mill and for big pockets the 25.4mm mill.

i learned that i don't have to make mistakes because i can damage the machine or break the mill. So i have to be carefull when i generate the files in Part works. The simulation helps a lot but i have to be sure about the position of each thing.

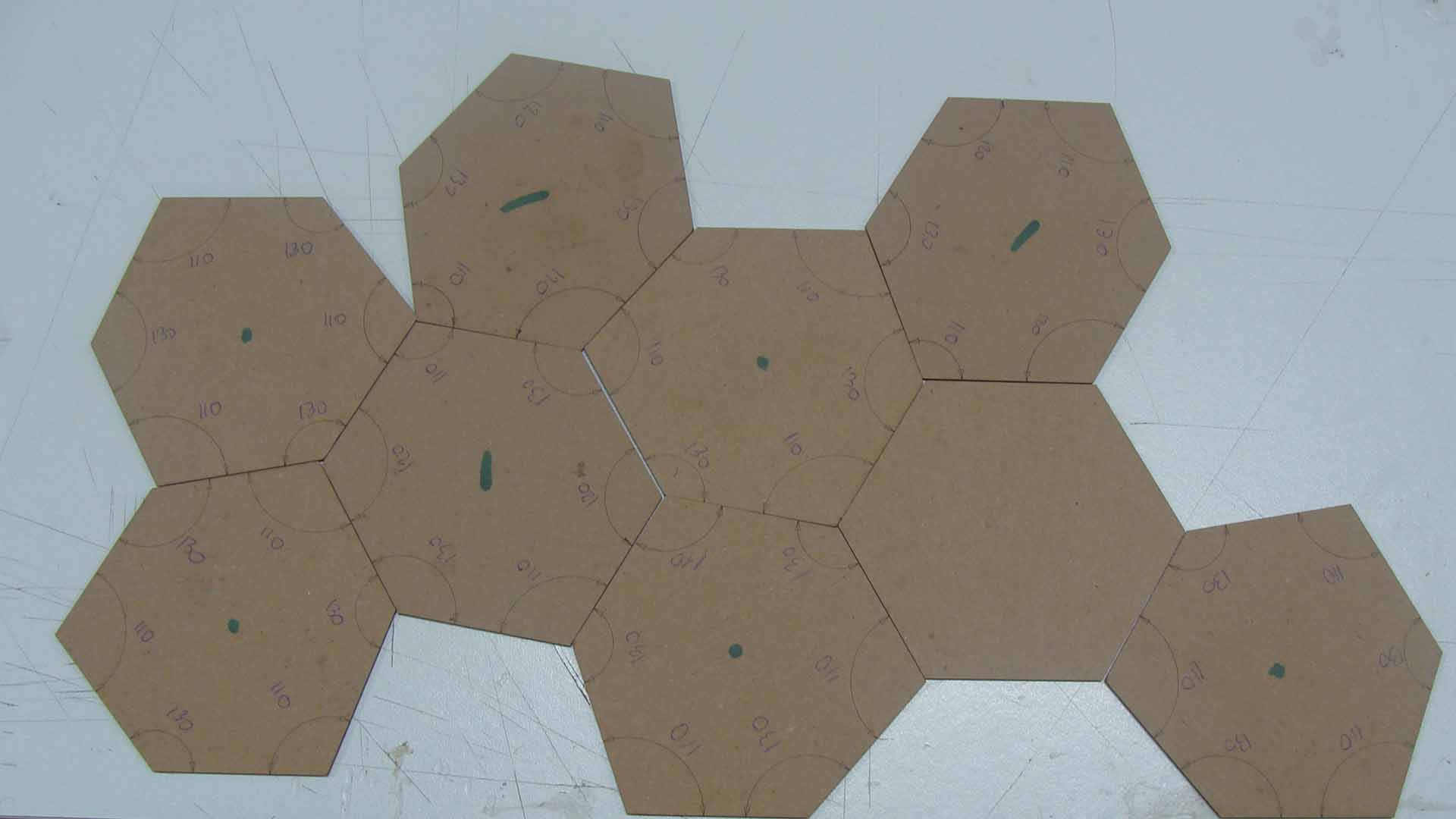

My own furniture a hexagon library. Actually i wanted to create a library with modular irregular hexagons. I designed 3 moduls, a regular and two irregulars. this is the composition of the library in a schema.

Unfortunatly i m still thinking about the design and i just made two moduls to make a prototype. As soon as i finish it i m going to upload it here in my website.

this is my preliminary modul

Recomendation:

Following my own experience of Industrial Designer i would recommend to use the shopbot machine mixed with another process or different materials, in order to develop a good product, at the begiining of this assignment i though i should make for example a furniture using only shopbot and mdf or plywood, now i think is better to make for example a connector with steel or search for different alternatives.

Soon more about Computer Controlled Machining

.

.

.

After this experience i wanted to develop a system that could be adaptable to different spaces. The client: ME

The new system should be more simple and should be used as bookcase or as shelf for different uses. It should be used for organize my own atelier or the different things that we have on a fablab. Books, tools, materials, etc.

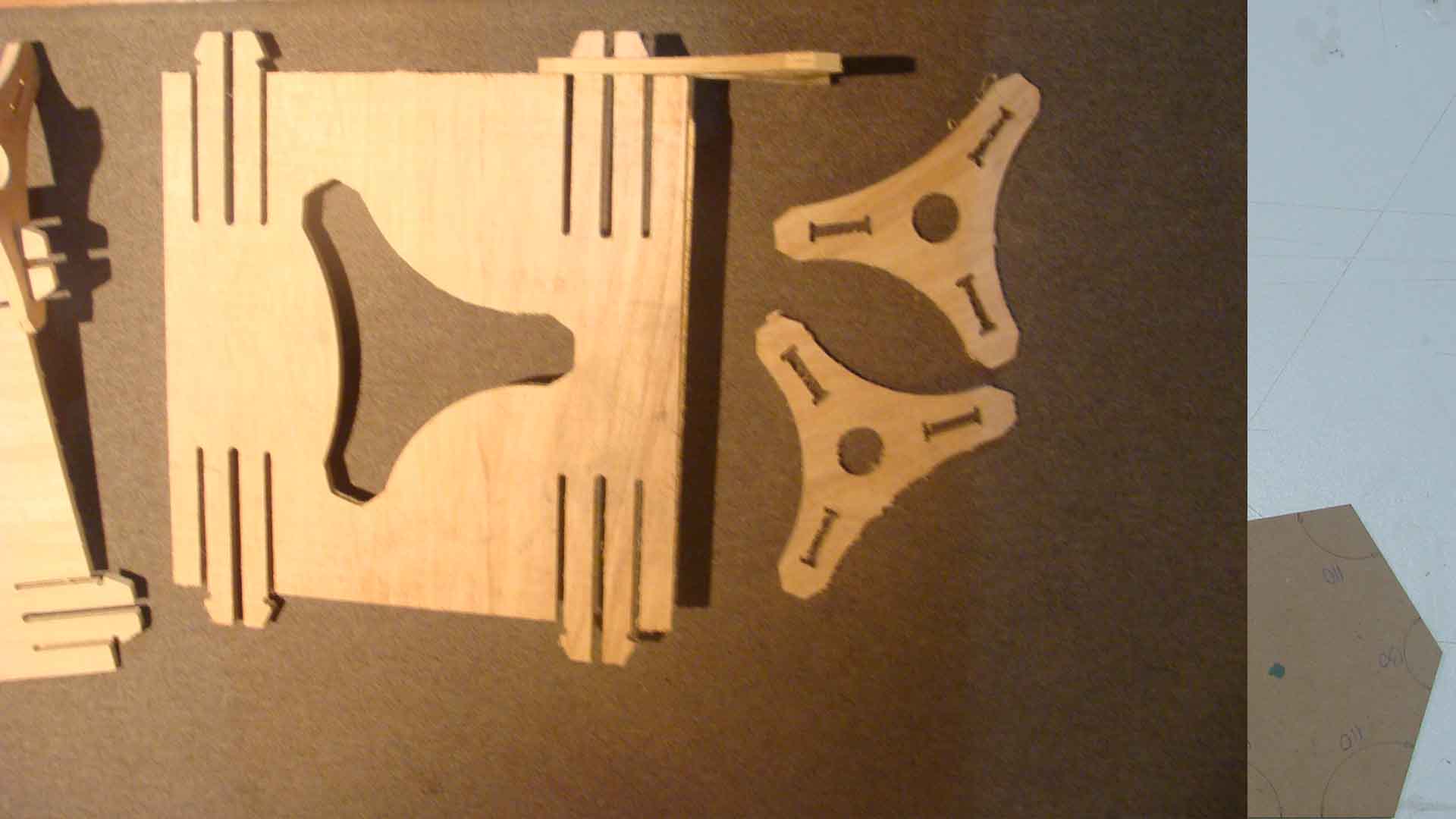

First I developed the system using the laser machine, i worked with mdf 3.2mm for creating a constructive system, this part was very funny because it could be used also as toy. This was amazing because i was not sure about that, then i saw my friends playing with this system and they built animals cars, planes different things.

.jpg)

.jpg)

Then appear the idea to create an interface to give the user the posibility to manage the configuration of his shelf. It could be more interesting and easy for the first stage of this project to include in the shop the laser fabricated model in scale 1/5 for making tests.

After this process I developed the big model is really strong and solid, ideal for books or tools. This first prototype will be for showing the different works on fablab here the photo:

Another plus of this furniture is that for transportation is not necesary a truck or a big car. At this photo we can see the pieces, a hammer and the assembled connector.

To assembly this furniture is necesary arround 40 minutes, but is possible to create many configurations.

This is the Cat into the furniture.

And finally this is fablab using my shelf to show some products and robots that were made in FabLab Uni

The FILES for building this system are on the next LINK

For Some inspiration for this assignment, a good example could be the project Talla Perú developed on FabLab UNI. More information about this project on the next Link